Confidence At Full Draw

A Broadhead Built For The Most Relentless Bowhunter

Lethal Enough For Every Big Game Animal On the Planet

Resilient Enough To Last Forever.

All of our broadhead blades are made out of high carbon spring steel because it’s incredibly resistant to bending, snapping and shattering.

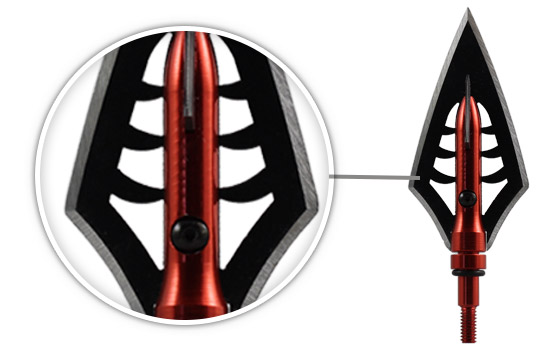

Stronger Than Metal Itself

The ferrule is precision cut out of aluminum and we bind the space between the ferrule and blade with a unique spot welding and copper brazing processes the creates a bond stronger than metal itself.

Easy To Sharpen

Stays Sharp Longer.

After years of testing and research, we’ve discovered that heat treating the broadhead to an incredibly narrow range of 48-51 Rockwell produces a blade that is easy to sharpen while still providing a lasting edge.

Easy To Sharpen

Stays Sharp Longer.

After years of testing and research, we’ve discovered that heat treating the broadhead to an incredibly narrow range of 48-51 Rockwell produces a blade that is easy to sharpen while still providing a lasting edge.

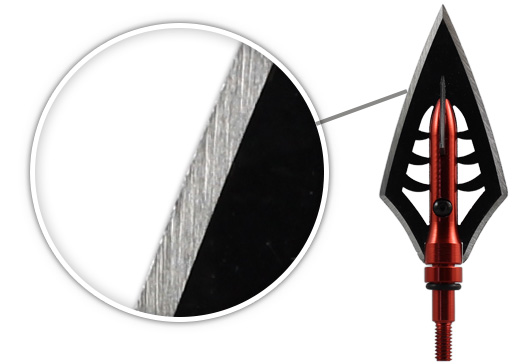

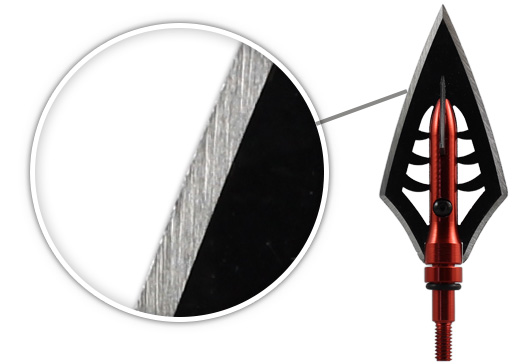

Ultimate Penetration

Special Teflon Coating Reduces Blade Friction

A great indication of a lethal shot is an arrow that passes right through the animal. Each of our broadheads feature a special Teflon coating that reduces friction and increases penetration.

Lethal Accuracy

After you release the string, the broadhead is the only thing that matters.

The most important aspect to an accurate broadhead is consistency in the build quality. All of our broadheads are precision built to our ruthless build standards. We inspect, weigh and hand spin each broadhead before it’s shipped to ensure only the best products leave our shop.

What Customers Say About Our Broadheads

I have spent a considerable amount of time looking for a decent fixed blade broadhead. The most important thing to me is a sharp blade and maximum penetration. A friend told me about these broadheads and I’m glad he did. So far I have taken my first bull Elk, Idaho Black Bear and a really tasty forky mule deer. I’m pretty sure I shot them all with the same exact broadhead. Its my new lucky charm in my quiver.